Contact Number:15980782353

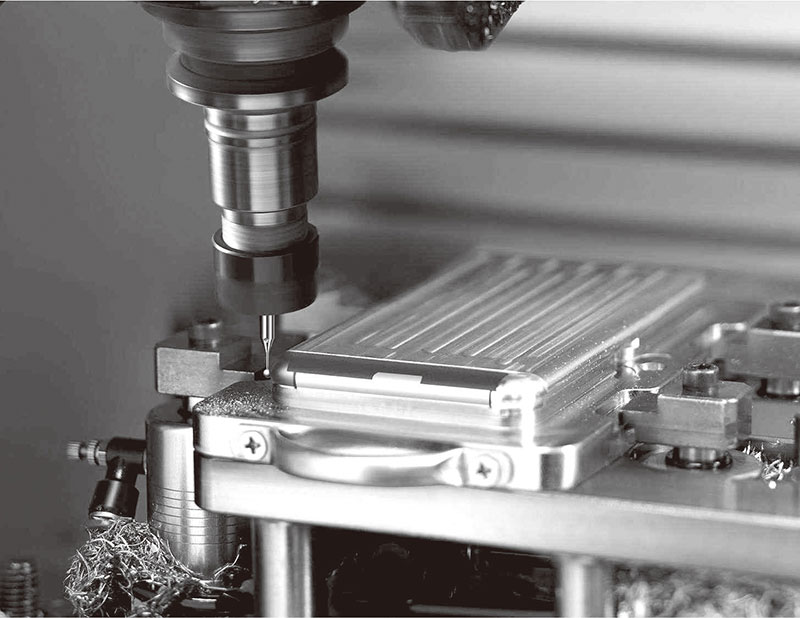

What are the advantages of high-speed cutting in vertical CNC machining centers

On the one hand, high-speed cutting of vertical machining centers. During high-speed cutting on a vertical machining center, the tool and workpiece can maintain low temperatures, which in many cases extends the tool's lifespan. On the other hand, in high-speed cutting, the cutting amount is small. The cutting time of the cutting edge is particularly short. That is to say, the feed time is shorter than the heat propagation.

Low cutting force results in small and consistent tool bending. This, combined with a constant inventory required for each tool and process, is one of the prerequisites for safe machining.

Due to the small cutting depth and radial force on the tool and spindle in high-speed cutting, the wear of spindle bearings, guide rails, and ball screws is reduced. High speed cutting and axial milling are also a good combination It has a small impact force on the spindle bearings. When using this method, longer cutting tools can be used with little risk of vibration.

High productivity cutting of small-sized parts. Such as in rough machining, semi precision machining, and precision machining processes It has good economy when the overall material removal rate is relatively low.

High speed cutting can achieve high productivity and good surface quality in precision machining. The surface roughness value is often lower than R 0.2

The vertical machining center adopts high-speed cutting Make cutting of thin-walled parts possible. Using high-speed cutting to process thin walls reduces impact and deformation due to the short cutting time.

Improve the geometric accuracy of the mold Assembly is easier and faster. High speed cutting can achieve excellent surface texture and geometric accuracy. If more time is spent on cutting, the manual polishing time can be significantly reduced.

Vertical machining centers use high-speed cutting, which can greatly reduce some machining processes such as quenching, electrochemical machining, and electrical discharge machining (EDM). This can reduce investment costs and simplify logistics supply. Replacing electrical discharge machining (EDM) with cutting also improves durability, tool life, and mold quality.